|

|

|

|

Applications

for Electrically Conducting

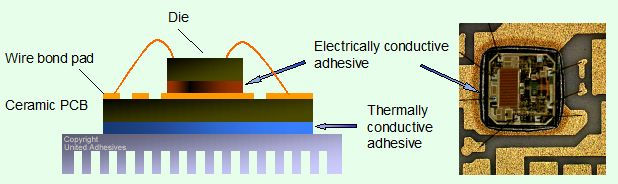

United Adhesives Inc. makes two categories of Electrically

Conductive Adhesives (ECA), silver filled silicones (Silductor

series) and silver filled epoxies (Eposolder series), in

both one-part and two-part systems. They are either dispensable

or screen /stencil printable. The Eposolder series provides superior bonding

strength to most common metal/alloy surfaces while maintaining

high electrical & thermal conductivity.

The typical applications are for mounting of heat sensitive

dies or components in sensors, disk drive, flip-chip, die

attach assembly or packaging, MEMS, LED Driver IC’s, CCD

chip attach, wafer lamination, CSP. Epoxy based ECAs provide

electrically conductive bonding between components and mounting

surfaces, and serve as thermal interface material for conducting

heat through heat spreader. They are alternatives for solder

replacement, chip bonding, and lead terminations.

|

|

| |

Click the name of the adhesive in following Table to access

its technical datasheet (TDS) in PDF file.

|

|

|

|

Name

|

Features / Advantages

|

Rheology

|

Part

|

Volume Resistivity

(Ohm-cm)

|

Hardness / Modulus

|

Adhesion

Al/Al, psi

|

Cure Rate

|

|

Silductor 6310

|

High conductivity. Low

stress silicone based. High moisture resistance. Reworkable.

|

41,000 cPs

|

1-part

|

< 5x10―4

|

Shore A = 45

|

>150

|

125C 60 min

|

|

Silductor 6350

|

Low cost alternative with Ag coated Cu as conducting media

|

42,000 cPs

|

1-part

|

< 2x10―3

|

Shore A = 68

|

>180

|

125C 60 min

|

|

Silductor 6381

|

Low cost alternative with Ag and Cu hybrid as conducting media

|

85,000 cPs

|

1-part

|

< 1x10―3

|

Shore A = 80

|

> 230

|

125C 60 min

|

|

Eposolder 6510

|

High electrical conductivity. Strong bonding strength. Dispensable

and printable

|

35,000 cPs

|

1-part

|

< 2x10―4

|

Shore D = 78

|

> 1200

|

125C 1hr, or 85C 2 hrs

|

|

Eposolder 6537

|

Fast cure (snap cure) epoxy-silver. Strong bonding strength. Dispensable

and printable

|

48,000 cPs

|

1-part

|

< 2x10―4

|

Shore D = 85

|

> 1500

|

180C 15 sec, 125C 5 min

|

|

Eposolder 6763

|

Epoxy based low cost alternative with Ag coated Cu as conducting

media

|

47,000 cPs

|

1-part

|

< 5x10―3

|

Shore D = 60

|

> 800

|

125C 60 min

|

|

Eposolder 6869

|

High electrical and thermal conductivity (11 W/mK). Strong bonding

strength

|

98,000 cPs

|

1-part

|

< 1x10―4

|

Shore A = 70

|

> 400

|

125C 60 min

|

|

Other Products

|

Eposolder 6503,

6520,

6522,

6526,

6761

– One or two part epoxy based systems with various

modifications

E-Shielding products, including acrylic Ag-Cu based

E-Shield

6037 and carbon based E-Shield

6410, provide conductive coating, RF / EMI shielding solutions

Refer to website to check the details of the properties

|

|

Anisotropic conductive adhesives (ACA) provide high-speed interconnection

for flip chip, fine pitch chip-on-film (COF), and

chip-on-glass (COG) LCD packaging, and various fine

pitch assemblies. They are often used as interconnect

material in mainstream applications such as flat panel

displays, LCD, smart card, camera modules, mobile

phones, direct access sensors, semiconductor packages

and RFID tags.

United Adhesives makes Au-based ACAs,

and Ag-based low cost ACAs for these applications. They all have a rapid snap-cure speed at elevated temperatures in

seconds with a thermo-compression. They forms a structural

bonding to various substrates and films with conductivity

only in z-direction while remaining insulation in

the x,y plane.

|

|

| |

|

|

|

Name

|

Features / Advantages

|

Rheology

|

Part

|

Volume Resistivity

(Ohm-cm)

|

Hardness / Modulus

|

Adhesion

Al/Al, psi

|

Cure Rate

|

|

AE6080

|

Z-axis anisotropic electrically conductive adhesive. Gold coated

nickel as filler, 2.5 um. Snap cure with compressing

|

26,000 cPs

|

1-part

|

> 1x10―12 (x, y dir);

z dir < 0.1 Ohm-mm2

|

Shore D = 88

|

> 1800

|

180C 4 to 6 sec. 150C 20 sec

|

|

AE6075

|

Z-axis anisotropic electrically conductive adhesive. Gold coated

nickel as filler, 5.0 um. Snap cure with compressing

|

25,000 cPs

|

1-part

|

> 1x10―12 (x, y dir);

z dir < 0.1 Ohm-mm2

|

Shore D = 86

|

> 1600

|

180C 4 to 6 sec. 150C 20 sec

|

|

AE6025

|

Z-axis anisotropic electrically conductive adhesive. Silver coated

copper as filler, 6.0 um. Snap cure with compressing

|

25,000 cPs

|

1-part

|

> 1x10―12 (x, y dir);

z dir < 0.5 Ohm-mm2

|

Shore D = 82

|

> 1600

|

180C 4 to 6 sec. 150C 20 sec

|

|

|

|

|