|

|

|

|

|

Optical

Applications

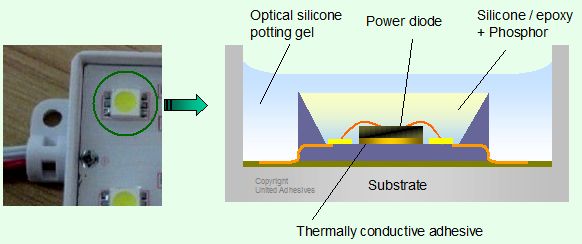

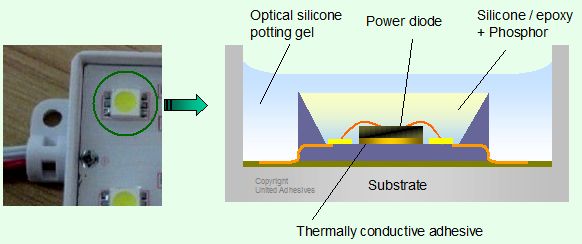

United Adhesives Inc. provides innovative solutions for

optoelectronics with optical-grade epoxy and silicone encapsulants,

coatings, adhesives, and sealants. They are applied in bonding

and potting fiber-optic cables, connectors and terminations,

LCD backlighting, displays, traffic and other lightings,

upgrading the vibration and shock resistance of electro-optic

assemblies, cementing and coating optical parts, potting

LED devices, optical replications, and coating or encapsulating

a wide variety of electro-optic and laser components.

They have the following features.

- Excellent light

transmission characteristics.

- Superior non-yellowing

properties or anti-yellowing

- Silicone based system

can cure to low-stress elastomer

- Resistance to ozone

and UV Degradation

- Broad operating

at temperatures of -40 to 180°C.

- High adhesion, high

purity, moisture resistance

- Reworkable for silicones

Click the name of the adhesive in following Table to access

its technical datasheet (TDS) in PDF file.

|

|

|

Name

|

Features / Advantages

|

Rheology

|

Hardness / Modulus

|

Refractive Index

(nD @ 25C)

|

% Transmission

(350 nm to 1000 nm)

|

Flexible Strength (FS) or

Tensile Strength (TS)

|

Cure Profile

|

|

OE1582

|

Optically clear epoxy. 2-parts,

cures at room temperature or can be accelerated at elevated

temperatures. Anti-yellowing formulation

|

2:1 mixing,

7240 cPs

|

70

(Shore D)

|

1.564

|

95% to 99%

|

F.S. = 120 MPa

|

80C 60 min

125C 15 min

|

|

OE1581

|

Optically clear epoxy. 1-part ready to apply, cures at elevated

temperature. Anti-yellowing formulation

|

1-part liquid

3470 cPs

|

70

(Shore D)

|

1.564

|

95% to 99%

|

F.S. = 120 MPa

|

85C 2 hrs

125C 30 min

|

|

OP4036

|

Optically clear silicone tough rubber, 2-part ready to apply. Transparency,

non-yellowing. Compliance to thermal stress

|

1:1 mixing,

4,900 cPs

|

40

(Shore A)

|

1.41

|

97% to 99%

|

N/A

|

80C 10 min

65C 20min

|

|

OP4035

|

Optically clear silicone tough rubber, 1-part ready to apply. Transparency,

non-yellowing. Compliance to thermal stress

|

1-part liquid

4,600 cPs

|

35

(Shore A)

|

1.41

|

97% to 99%

|

N/A

|

125C 60

min

|

|

|

|