|

|

|

|

Applications

for Thermal Conducting and Heat Dissipation

United Adhesives Inc. makes thermally conductive adhesives

(TCA) for bonding electronic devices with heat dissipations.

They have following features:

· Very high thermal conductivity.

· High bonding strength to most common

plastics and metals

· Soft rubber and flexible (Thermondbond

series) to couple thermal stress while dissipating heat

· High dielectric strength for voltage

insulation

Potential Uses

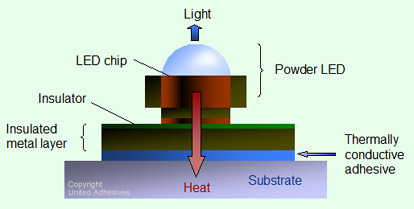

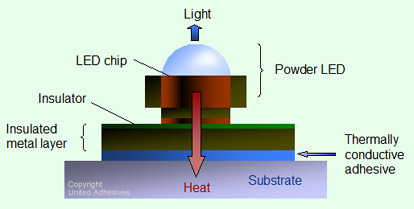

For high heat dissipation bonding in automotive electronics,

semiconductors, and telecommunications, typically applied

between a high heat power device and heat sink; any places

where require coupling thermal stress while dissipating

heat, or require thermally conductive vibration dampening;

attachment of PCB to heat sink, cooling fans to devices,

bonding or encapsulation of powder devices.

Click the name of the adhesive in following Table to access

its technical datasheet (TDS) in PDF file.

|

|

|

|

Name

|

Features / Advantages

|

Rheology

|

Part

|

Thermal Conductivity

|

Hardness / Modulus

|

Adhesion

Al/Al, psi

|

Cure Rate

|

|

Thermobond 3513

|

Silicone with high bonding Strength. Low stress

|

Flowable

56,000 cPs

|

1-part

|

1.4 W/mK

|

Shore A =70

|

> 600

|

125C

60 min

|

|

Thermobond 3517

|

Silicone with high thermal conductivity. Strong bonding. Non-Slump

|

Thixotropic,

120,000 cPs

|

1-part

|

1.9 W/mK

|

Shore A = 90

|

> 550

|

125C

60 min

|

|

Thermobond 3831

|

Boron nitride filled for very high thermal conductivity

|

Thixotropic,

230,000 cPs

|

1-part

|

3.2 W/mK

|

Shore A = 63

|

580

|

125C

45 min

|

|

ET1628

|

High thermal conductivity. High bonding Strength. Easy flow. Rmt

curable.

|

220,000 cPs

|

2-part

2 : 1

|

2.3 W/mK

|

Shore D = 70

|

> 1500

|

25C 8hrs, or 105C 10 min

|

|

ET1643

|

High thermal conductivity. High bonding Strength. Easy flow. Low

CTE.

|

210,000 cPs

|

2-part

1 : 1

|

1.7 W/mK

|

6.7 GPa

|

> 1800

|

25C 18hrs, or 125C 30 min

|

|

ET1645

|

High thermal conductivity. Good flow. High bonding Strength.

|

50,000 cPs

|

1-part

|

2.3 W/mK

|

Shore D = 90

|

> 1000

|

125C

30 min

|

|

TF2619

|

High thermal conductivity gap filling silicone

|

Thixotropic,

230,000 cPs

|

1-part

|

1.9 W/mK

|

Shore OO=40

|

N/A

|

125C

45 min

|

|

Eposolder 6869

|

Silver filled epoxy for extremely high thermal conductivity

|

98,000 cPs

|

1-part

|

11 W/mK

|

Shore A = 70

|

> 400

|

125C

60 min

|

|

Other Products

|

Thermobond 3508,

3519,

3821,

3830

– One or two-pat silicone systems with various modifications

ET1608,

1642,

1645NS,

1653BN,

1655,

1658

– One or two part

epoxy systems with various modifications

Refer to website to check the details of the properties

|

|

|

|

|